Cutting boards

Cutting boards make the perfect gift for anyone in your life. Whether you need a hardworking kitchen tool, an occasional cheese board, or a cherished display piece, you have come to the right place!

Board Butter and You!

If you purchased a cutting board from B Van The Craft Man, or were gifted one of our boards by someone who cares about you, then you are also the proud owner of a tin of homemade Board Butter!

Board Butter is a blend of all natural waxes and oils (Linseed Oil, Carnauba Wax, Bees Wax) used to finish and seal your cutting board during the manufacturing process. Our Board Butter is all natural, food safe, and guaranteed to add longevity and a renewed sheen to your cutting board! Although your frequency and intensity of use will vary, you should reapply your Board Butter after about a month to keep the wood sealed and in tip top shape.

Here’s How:

- First, find a cloth or rag that you do not mind potentially being your butter rag forever, as the Linseed oil can be a bit tricky to get out of cloth. Preferably find something that does not shed fibers.

- Next, open your tin, rub the rag against the surface of the butter applying pressure as needed to start mixing up the substance. You want to work your Board Butter until it transforms from a hard wax consistency to one that more resembles a smooth melty….well butter!

- Then, scoop up some of that butter with your cloth and apply it generously to the top surface of your board. More butter is always better, you will wipe away the excess later.

- Now, massage the butter across the board, making sure to get into all the grooves, crevices, and designs. Once the whole board is nicely buttered, you want to start wiping off the excess in the direction of the wood grain. You should be left with a thin oily coating over the entire board and minimal obvious streaks or strokes from the cloth.

- Finally, Let the board sit in a dry, room temperature location for at least 24 hours before handling. The board will be fully cured and ready for heavy use after 72 hours.

If your board is especially nicked, grooved, cut or otherwise damaged, you can start this process by going over the top surface of the board with fine grit sandpaper to smooth out the imperfections. Just be sure to clean the board of dust and if it gets wet for any reason during or after the sanding process, make sure to let it dry fully before sealing it.

Wood Species

A List of currently in stock wood species that we offer for cutting boards.

- Acacia :

- Pros

- Naturally resists moisture and bacteria.

- Resistant to scratches and dents

- Acacia trees are fast-growing and renewable, making this a sustainable choice.

- Cons

- While durable, acacia requires some maintenance to keep it ship-shape.

- Acacia’s hardness can lead to more wear on knives compared to softer woods like maple.

- Pros

Display vs Practical Boards

When ordering a board there is one very important question you need to ask yourself: Will this board be used for preparing food and serving snacks, or will it be a decorative piece?

Depending on the amount of contact with food you expect, the available customization options will change. This is to ensure that every board is as safe and durable as your needs demand.

Personalization Options

Make every board unique with a host of customization options!

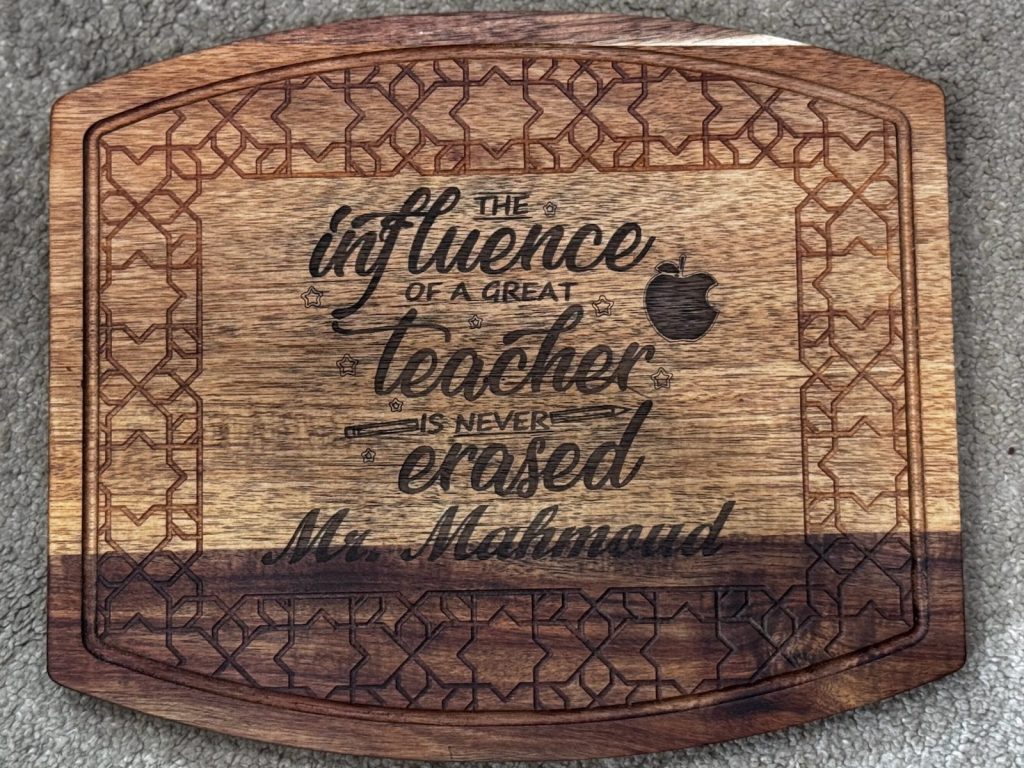

- Laser and CNC engraving

- Various stain and color options

- Custom text, images, patterns, etc.

- Front and/or back side engraving

- Multiple shapes and sizes